Digital Transformation is Your Companion in Textile and Apparel Industry: Bimser

The importance of digital transformation in the textile industryis increasing day by day. In order to keep pace with change, companies need to strengthen their infrastructure and accelerate transformation. The leading reasons forcing the textile sector to change can be categorized under the following headings.

In the last 10 years, the cost of processing power has decreased by 50 times, the cost of data storage by 20 times, the cost of bandwidth by 40 times, the cost of sensors by 50% and the cost of robots by 30%. Parallel to this, textile technology has also experienced a significant development in terms of both product and production technology. Customers’ expectations have changed both in terms of products and access methods. Demands for customized production and shorter delivery times are increasing day by day. New production technologies such as seamless manufacturing are further increasing customer expectations. Industry players need to make the necessary investments in corporate governance or back-office systems to manage these demands.

Virtual Reality (AR) With developing technologies such as developing technologies, accelerating and developing web, customers have the opportunity to examine their products in the virtual environment without going to stores and have the opportunityto compare different products. The current pandemic has made this habit even more common. Therefore, retaining loyal customers is not as easy as it used to be, and companies definitely need to make a difference. However, competitors, suppliers, customers reduce your company’s profitability.

It is increasingly important for manufacturers to be flexible and agile. Manufacturers that respond quickly to rapidly changing customer demands are preferred. Flexible demand management, shorter order times and direct-to-customer sales (ship to end-user) are becoming increasingly important for survival. All kinds of technological investments must be made in order for companies to keep the delivery times they have promised to their customers, to continue production as planned, and to minimize unexpected interruptions.

Due to the negative judgment that we all unfortunately have in the society about the environment, it is inevitable that players in the textile industryshould carry out environmentally friendly policies to reduce social pressure. The ability of organizations to produce sustainably is becoming an important purchasing factor for end consumers. The use of technology is a prerequisite for sustainability.

E-commerce, which is shaped by the use of digital technologies, enables firms to access and transact with potential customers, complementors and suppliers (including employees) in other countries at low costs, providing supply-side economies of scale.

More importantly, it increases firms’ profitability by generating demand-side economies of scale (prices increase as the number of customers and quantities sold increase), which can be added to e-commerce systemsthrough platformization, allowing international buyers, sellers and complementors to offer value to each other.

It is becoming more and more difficult to ensure that businesses stand out in the competitive environment and to eliminate digital discomfort points. Especially in the textile industry, increasing costs, high competition, high customer expectations and challenging supply chain management triggered the rapid start of digital transformation and digital transformation became inevitable.

The textile sector has to maximize the efficiency of their equipment investments. The longer the life cycles of the production equipment in question, the fewer unexpected outages of the equipment, the more beneficial it will be. The quickest way to achieve this is through a well-constructed

Corporate Asset Management

using the solution. With such a solution, they will also realize cost reductions by better managing their maintenance agreements and spare materials.

Integrated Management Systems, Enterprise Asset Management, Electronic Document Flow Management, Performance Management and Balanced Scorecard structures managing the future of your business is now extremely important. Systems that are integrated from the beginning to the end of the production process are used for efficiency, performance management, KVKK, e-signature, etc., especially corporate memory. The gains of digital technology, which provides optimization in many subjects, are as follows;

- Lower your costs.

- Provide more benefits to your customers.

- Increase your profitability.

- Increase your agility.

- Manage your suppliers faster and better.

- Model your processes.

- Reduce poor quality costs.

- Use all resources more efficiently.

Be among the winning companies that observe the principles of sustainability by making use of technology and are more sustainable by using the capabilities of technology.

We are ready with our 25 years of knowledge, more than 1800 active customers and our ecosystem of solution partners with Bimser products and sector-specific solutions.

Let’s plan your digital transformation roadmap together.

- Smart Watch, Smart Glasses

- Clothes that Connect with Sound, Brain Signals

-

Remotely Controlled Homes with Early Warning Feature (floor materials, home textile products)

-

Conformosite, Products That Can Adapt to the Changing Demands of People

-

Measuring, Logging, Performance Enhancing Clothing

- Clothing that Measures, Records and Communicates with the Hospital in Case of Emergency

- Clothing Compatible with Environmental Conditions

- Energy Producing and Storing Surfaces

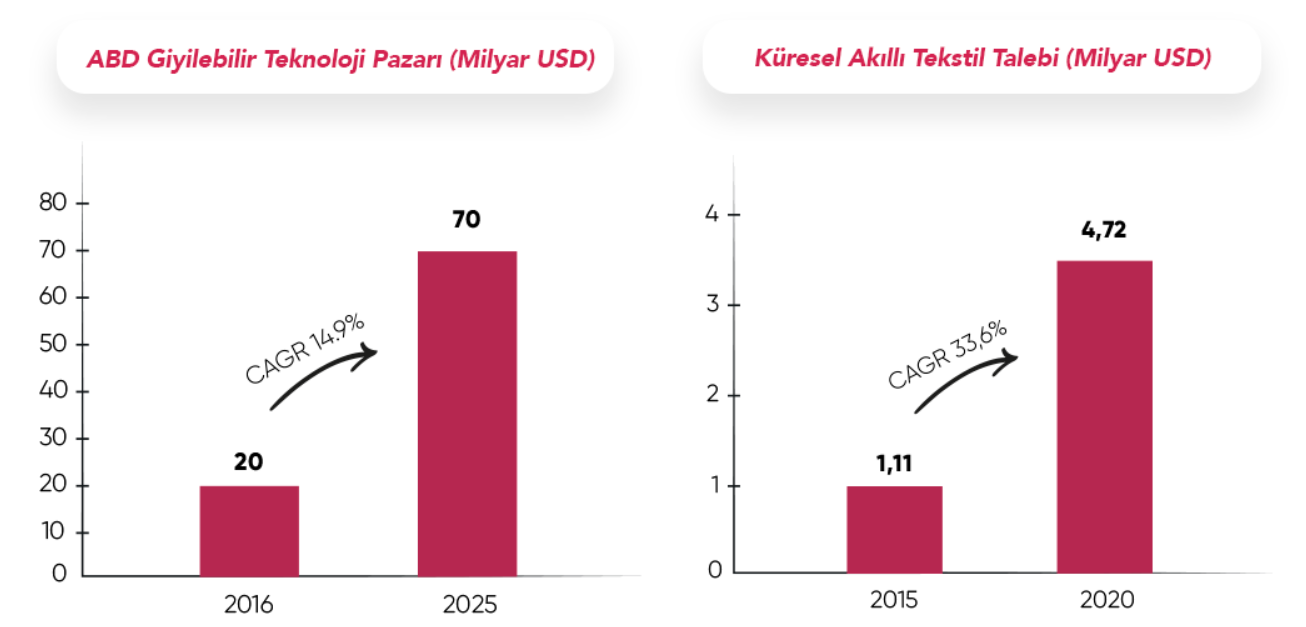

According to the predictions, by 2025, 10% of the world’s population

10% will use wearable technologies that can connect to the internet

- Yarn, fabric, garment loop

- From agriculture and chemistry to textiles

- Electronics integrated into clothing

- From electronics and textiles to apparel

- Textile, electronics and nanotechnology working together

- Organic conductive fibers and solar cells